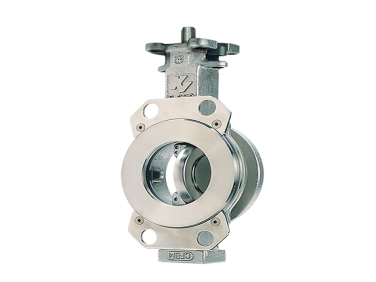

Keystone K-LOK Figure 360/362 and 370/372 High Performance Butterfly Valve

006485-HW-KEYSTONE-085

Overview

The Keystone K-LOK Figure 360/362 and 370/372 is a high performance butterfly valve rated to ASME Class 150 and Class 300 that provide bi-diectional, drop-tight closure. These valves are available in a variety of materials to optimize reliabiliy, no matter the application.

| Material | 316 Stainless Steel, Carbon Steel, Duplex, Monel, Stainless Steel, Steel, Super Duplex, Teflon |

| Pressure Class | ASME |

| Process Connection Type | CL150RF, CL300RF |

| Seat/Seal Type | High performance, Metal, Resilient, Soft, Soft Seal |

| Shutoff Class | Class IV (FCI 70-3), Zero Leakage |

| Standards | API 609, ASME B16.34 |

| Valve Size | PS 10 / DN 250, NPS 12 / DN 300, NPS 14 / DN 350, NPS 16 / DN 400, NPS 18 / DN 450, NPS 2 / DN 50, NPS 20 / DN 500, NPS 2-1/2 / DN 65, NPS 24 / DN 600, NPS 3 / DN 80, NPS 4 / DN 100, NPS 6 / DN 150 |

| Valve Size Standard | NPS |

| Valve Type | Butterfly |

| Shutoff Class | Class IV (FCI 70-3), Zero Leakage |

| Standards | ASME B16.34, API 609 |

| Valve Size | PS 18 / DN 450, NPS 2 / DN 50, NPS 20 / DN 500, NPS 2-1/2 / DN 65, NPS 24 / DN 600, NPS 3 / DN 80, NPS 16 / DN 400, NPS 4 / DN 100, NPS 8 / DN 200, NPS 6 / DN 150, NPS 14 / DN 350, NPS 10 / DN 250 |

| Valve Size Standard | NPS |

| Valve Type | Butterfly |

The integrally cast mounting pad on this product allows for the direct and easy attachment of various actuators, streamlining installation and enhancing overall functionality. The rocker-shaped gland bridge compensates for uneven adjustments of gland nuts, ensuring smooth operation even when misalignments occur. Additionally, the extended neck design provides ample room for up to two inches of pipeline insulation, which is essential in maintaining thermal efficiency and protecting the system from external conditions.

The body of the valve features a flattened bore at the shaft journal ports, which positions the shaft bearings close to the disc. This design provides superior shaft support, minimizing wear and extending the lifespan of the valve. Another innovative feature is the tangential positioning of the disc taper pins, with half embedded in the disc and half in the shaft. By placing the pins in compression rather than shear, the potential for failure is significantly reduced, increasing the reliability of the valve.

An integrally cast disc position stop ensures that the disc is perfectly located within the seat, optimizing seat and seal life. Furthermore, the valve is equipped with seats made from various materials, allowing for extended service life across different applications. This versatility ensures that the valve can be tailored to suit specific operational needs, making it a robust solution for demanding environments.