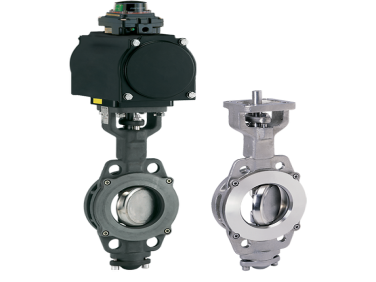

Keystone Series HiLok High Performance Butterfly Valves

006484-HW-KEYSTONE-084

Overview

The HiLok high performance Butterfly valves offer efficient, bidirectional sealing

| Certifications | SIL capable, PED, CUTR |

| End Connection | Lugged, Wafer |

| Application | Metals Processing, Fuel Gas, Facilities & Process Utilities, Blowers, Biofuels, Air Circulation |

| Material | Duplex, Carbon Steel, 316 Stainless Steel |

| Pressure Class | PN |

| Process Connection Type | PN25, PN16 |

| Seat/Seal Type | High performance |

| Shutoff Class | Zero Leakage |

| Valve Size | NPS 20 / DN 500, NPS 18 / DN 450, NPS 16 / DN 400, NPS 14 / DN 350, NPS 12 / DN 300, NPS 10 / DN 250 |

| Valve Size Standard | DN |

| Valve Type | Butterfly |

| Media | Air, Air, Inert Gas, Ammonia, Fuel Oil, Hot Water, Liquids, Specialty Gases, Natural Gas, Water, Vacuum, Steam, Oxygen |

| Stem | Live loaded, Adjustable packing |

The product features a cast-on ISO top plate that enhances stability and allows for easy mounting. Its long neck design is tailored specifically for insulation service, making it ideal for applications that demand effective thermal isolation. The external travel stop, located outside of the medium area, prevents over-extension and ensures the valve operates within its designed range. A key advantage is the accessible packing adjustment, which can be done without the need to remove the operator, offering convenience and reducing downtime during maintenance.

This product is engineered to provide positive sealing, which is mechanically achieved and does not rely on line pressure assistance, ensuring reliable performance under varying conditions. The valve also delivers bidirectional shut-off capabilities, making it versatile for different flow directions. Customers can choose from various seating options, including soft, fire-safe, and metal seated configurations, depending on the specific application requirements.

Durability is a standout feature, with a double-offset operating principle that minimizes seat wear, leading to an extended product life. The two-piece shaft design enhances flow capacity while reducing head loss, optimizing efficiency. Stability is further guaranteed by the quadruple shaft bearings, which are designed to handle high pressure and high cycle operations effectively. Seat replacement is fast and simple, minimizing downtime and ensuring continued performance. Lastly, the uninterrupted gasket surface provides a smooth and effective sealing interface, contributing to the overall reliability of the product in demanding applications.